Precision cutting : Redefining Roofing Standards

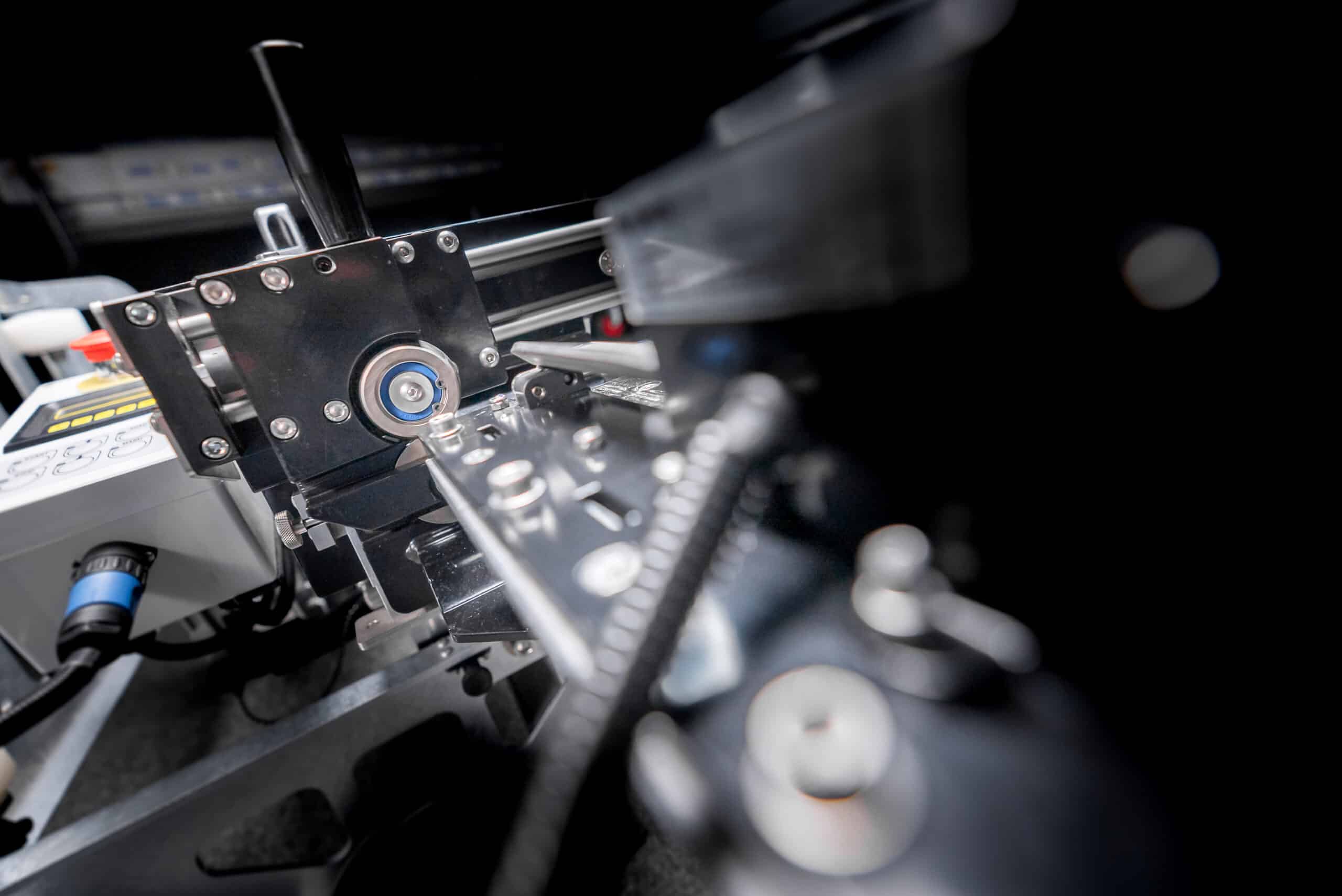

Innovation of the cutting module in the Dipro3x profiling machine

In the modern metal shaping industry, efficiency and precision are crucial elements to ensure the quality of final products. Among the many technological advancements, the cutting module on the profiling machine has revolutionized the way materials are processed. The profiling machine Dipro3x is much more than just a metal shaping machine. Equipped with an integrated cutting module, it offers unprecedented versatility in the production process. This pioneering profiling machine incorporates the cutting option to provide high-precision cutting results, meeting the strictest industry standards.

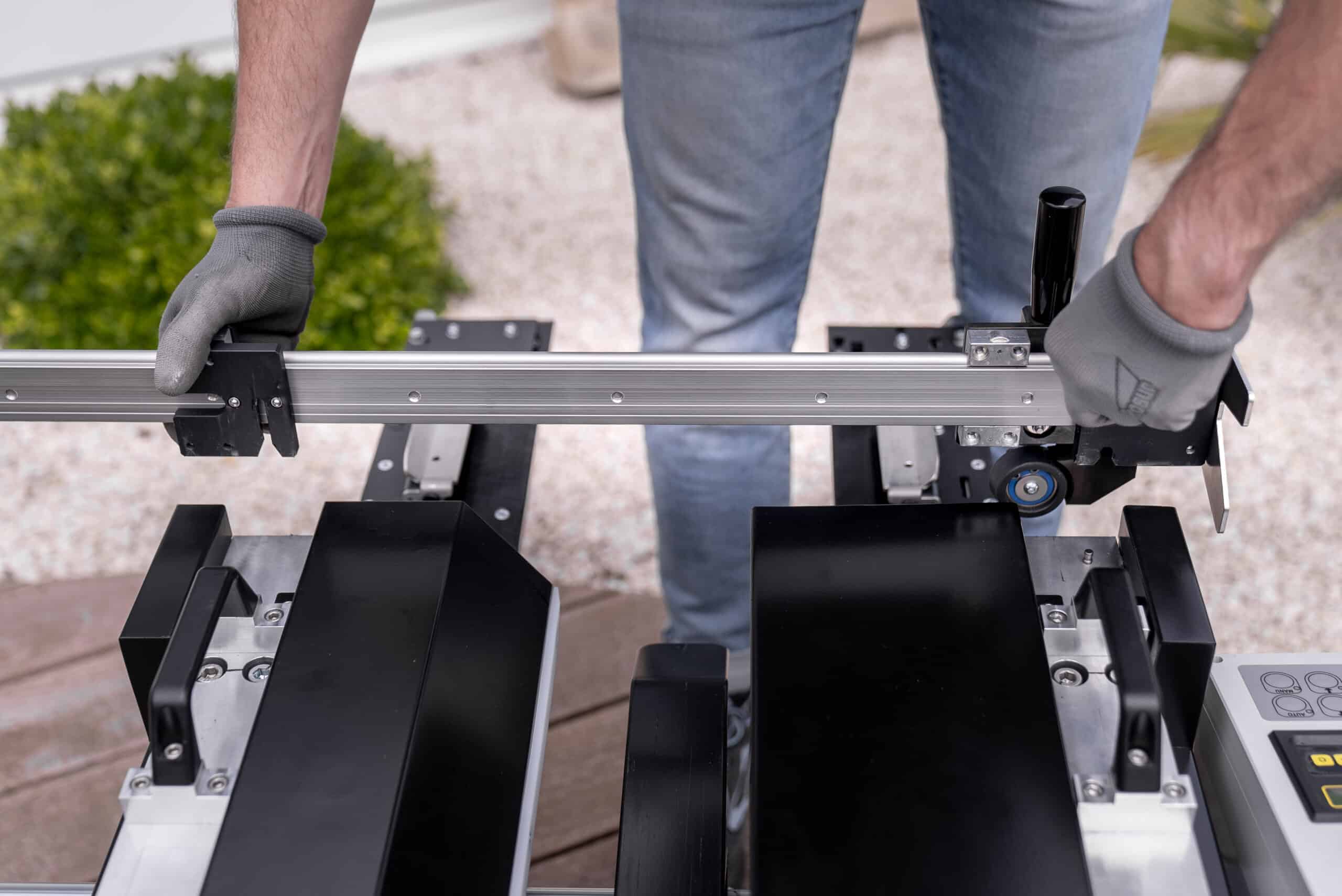

Workshop quality on-site with the Dipro3x profiling machine

One of the key advantages of the Dipro3x is its ability to ensure workshop quality on building sites. With its cutting-edge technology and 100% programmable control box, it ensures unmatched precision in shaping standing seam trays. Users benefit from smooth and easy manual cutting, allowing total control over the manufacturing process. This ease of use also reduces the need for specialized labor, resulting in additional savings for businesses.

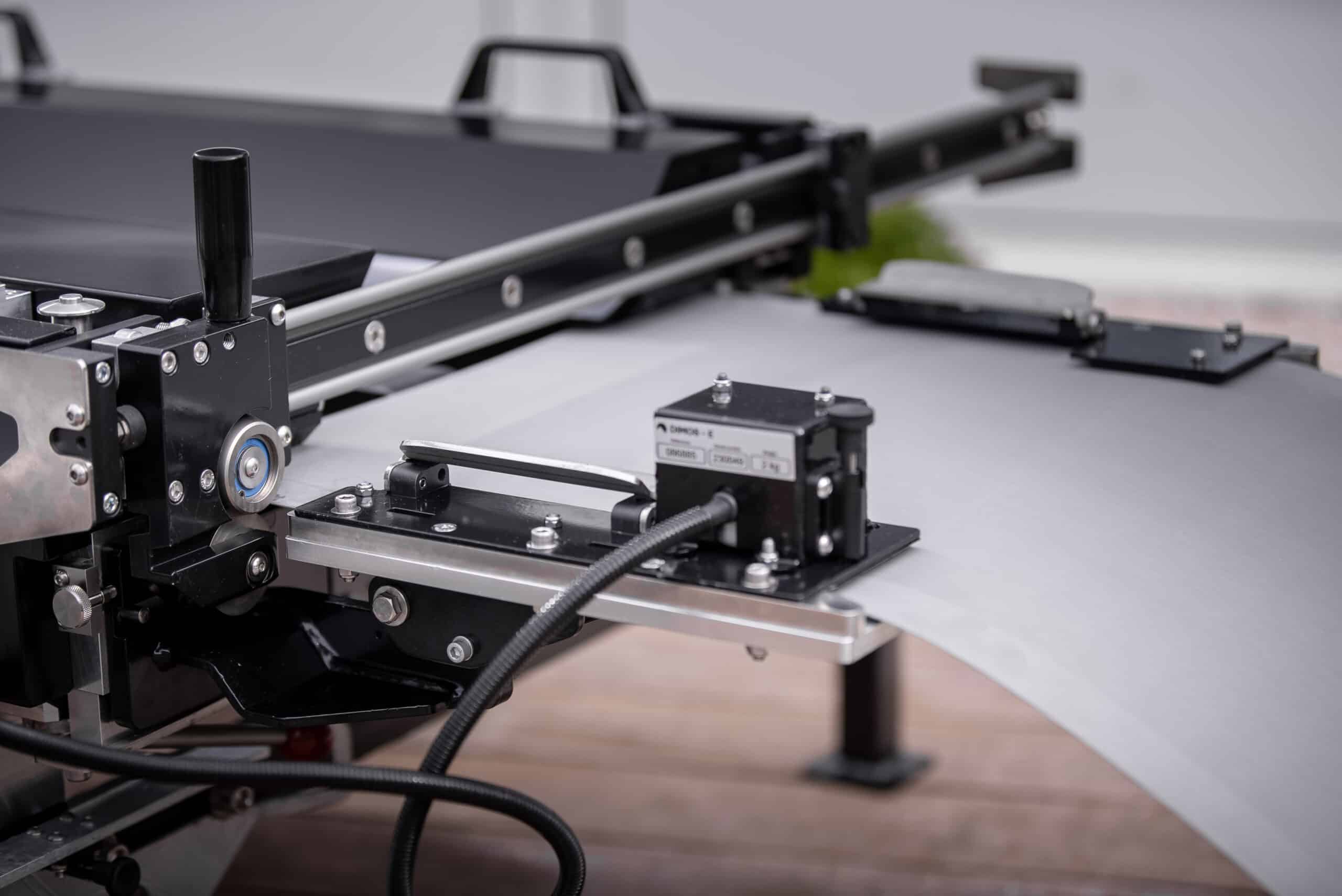

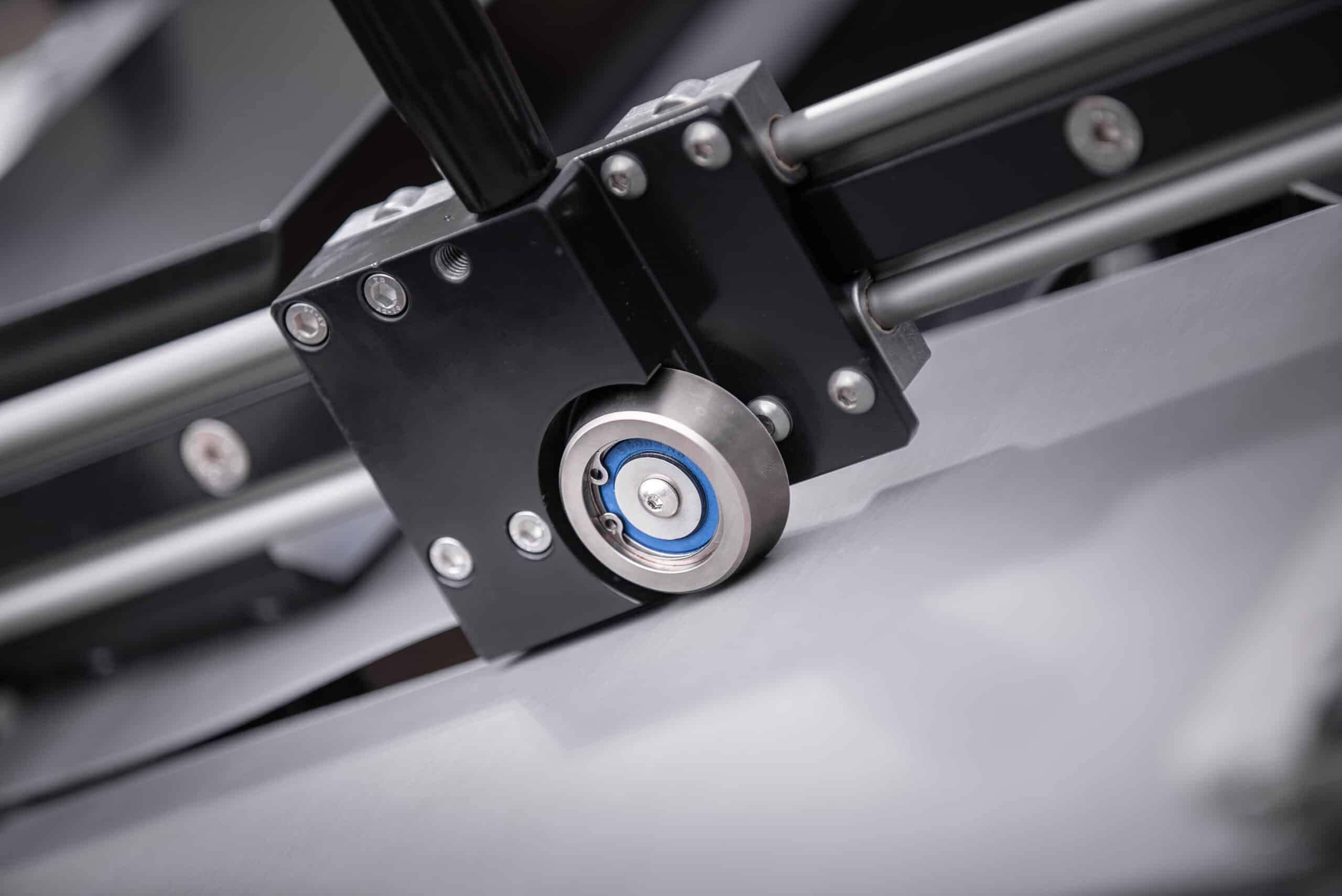

Material optimization with Double Circular Knife Technology

The integrated double circular knife technology in the Dipro3x profiling machine offers exceptional strength and increased durability. This highly resilient knife allows material optimization, reducing waste and maximizing material utilization. By integrating cutting upstream of profiling, the Dipro3x enables material optimization from the beginning of the manufacturing process. This approach reduces material losses and contributes to a more sustainable use of resources.

Flexibility and adaptability of the Dipro3x profiling machine

Furthermore, the Dipro3x profiling machine’s fully programmable capability offers unmatched flexibility in production. Operators can easily select the number and length of trays according to the specific requirements of each project, enabling quick customization and adaptation to each site's demands. This adaptability is particularly crucial in an environment where customer or architect demands evolve rapidly, and diversification of outputs is essential to remain competitive.

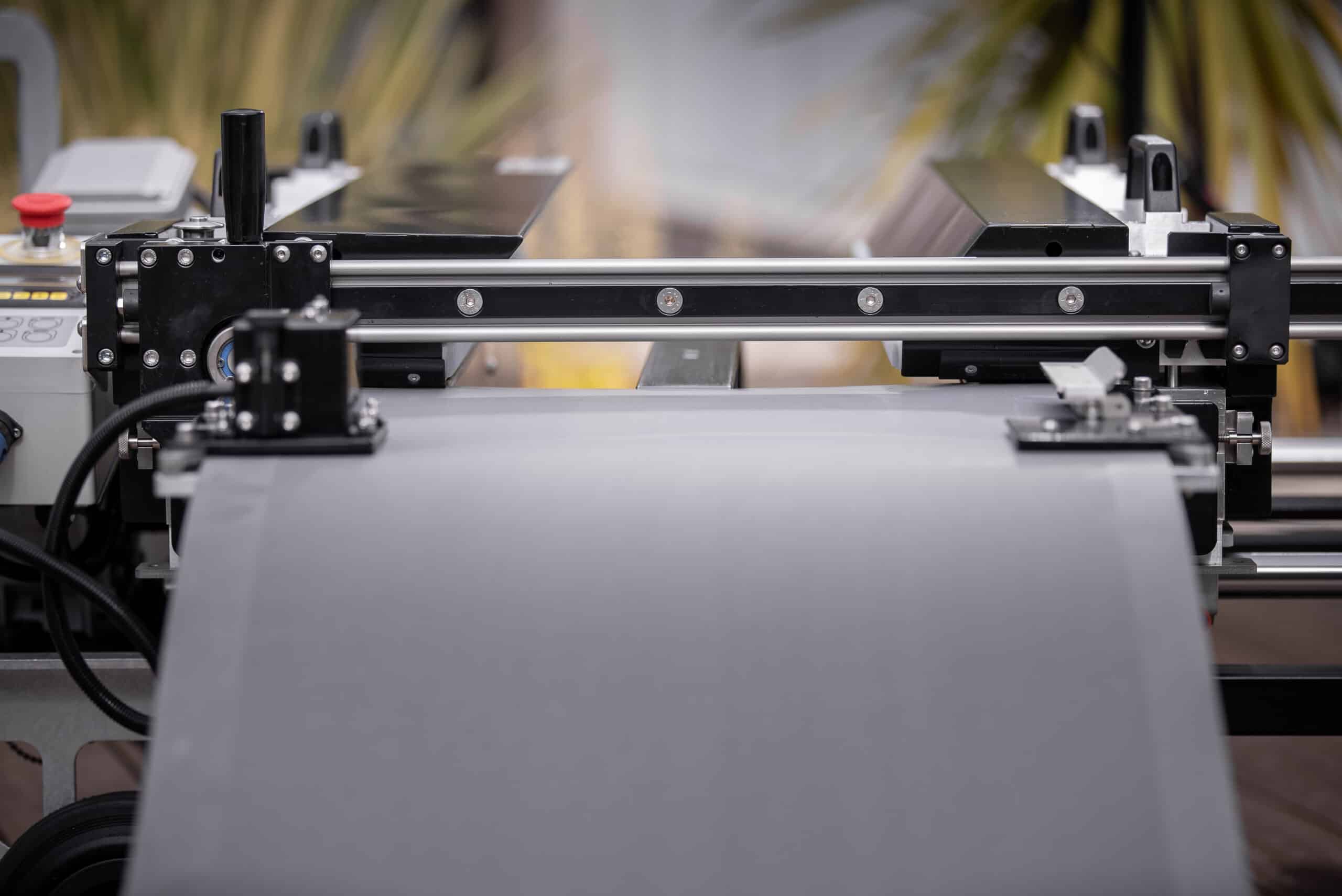

Cutting precision and consistent results with the Dipro3x profiling machine

The cutting precision of the Dipro3x profiling machine ensures consistent and high-quality results every time. Tight tolerances and precise repeatability are essential for applications such as metal roofing and cladding, where even small variations can lead to structural or aesthetic issues. This increased precision also allows manufacturers to reduce rework costs and ensure maximum customer satisfaction.

Impact of profiling machines with cutting module on the metal forming industry

In conclusion, the cutting module of profiling machines, especially the Dipro3x, represents a significant advancement in the metal shaping industry. With constantly evolving technology and increasing attention to sustainability, these machines will continue to shape the future of roofing and cladding markets. Their ability to offer exceptional efficiency, precision, and durability opens up new possibilities for roofers and contractors, while also contributing to a more responsible use of resources and sustainable production.

A legacy of excellence with the Dipro3x

In conclusion, the Dipro3x profiling machine represents concrete examples of French ingenuity and craftsmanship in the field of cladding and roofing. Its contribution to the industry, both technologically and economically, is undeniable, and its legacy will continue to inspire future generations of roofers and professionals. By combining innovation, quality, and French manufacturing, France positions itself as a global leader in creating cutting-edge roofing solutions, and its influence on the construction industry is felt worldwide.