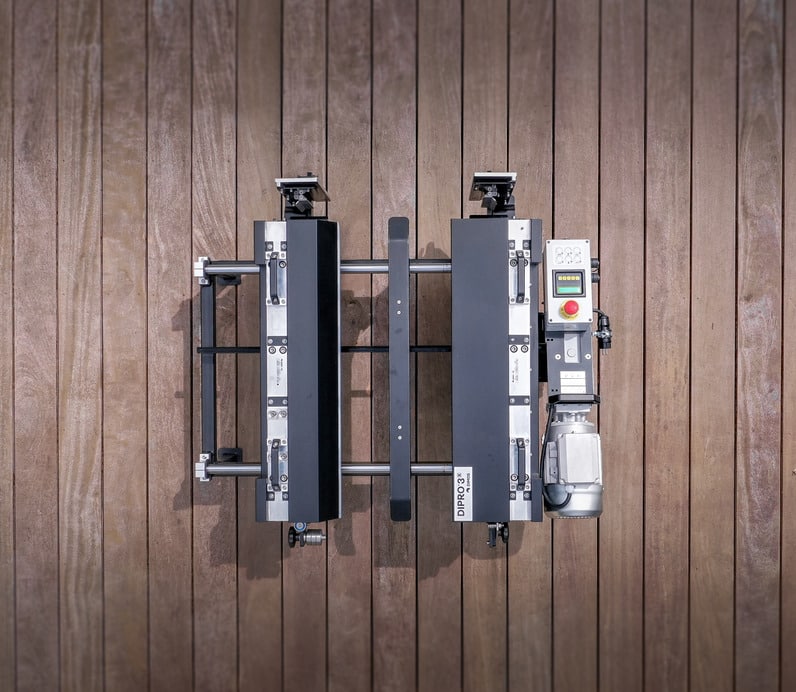

Dipro3x Profiling Machine

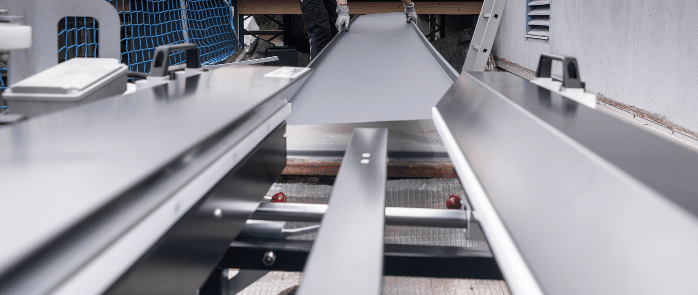

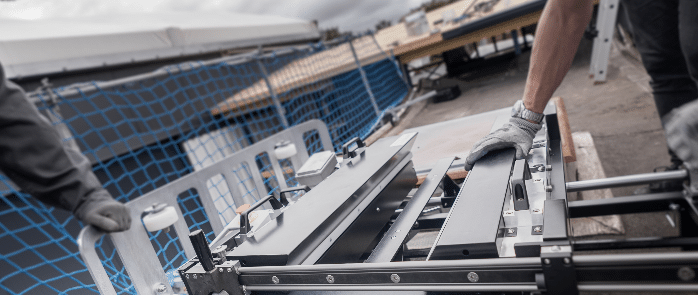

Turn every project into a masterpiece ! The Dipro3x profiling machine is just as adaptable in the workshop as it is on the building site. Its robust design ensures durability even in outdoor conditions. With its ability to profile quickly and accurately, it delivers professional-quality results every time and across a wide range of metals. This scalable machine offers a multitude of options to meet the diverse needs of both novice and experienced roofers and cladders. Its tool-free operation allows you to use it anywhere, anytime.

Material thickness

Min to max (mm)

Steel

0.4 to 0.75

Aluminium

0.4 to 0.8

Copper

0.4 to 0.8

Zinc

0.4 to 0.8+

Stainless steel

0.5

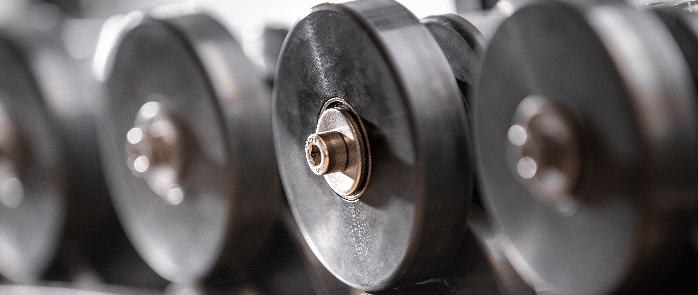

Premium-quality rollers

treated for superior durability and corrosion resistance

Non-profiling fonction included

on each train

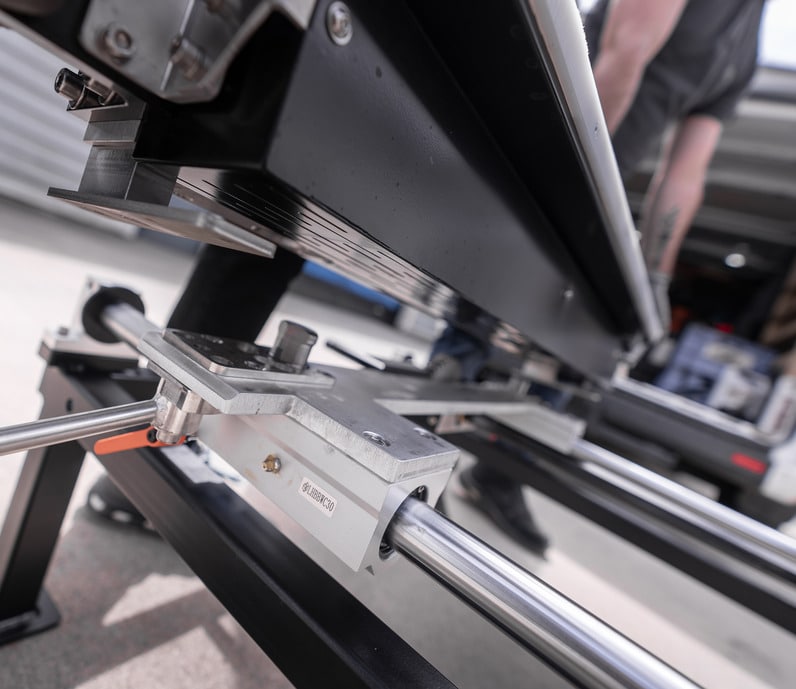

Profile maintenance guide

for the second pass included on each train

Integrated bending adjustment

device on each train

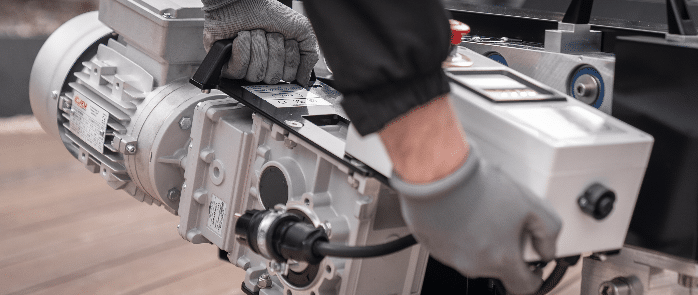

Zero desynchronization risk

and enhanced safety with a single engine

Anti-marking central support

for tray guidance

Outdoor conditions resistance

to ensure longevity

Profiling types.

Ideal for the square plan of standard roofing and cladding applications.

- Tray bottom width: 1 pass: from 157 to 722 mm

- Sheet width: 1 pass: from 235 to 800 mm

- Tray bottom width: 2 passes: starting from 62 mm

- Sheet width: 2 passes: Starting from 140 mm

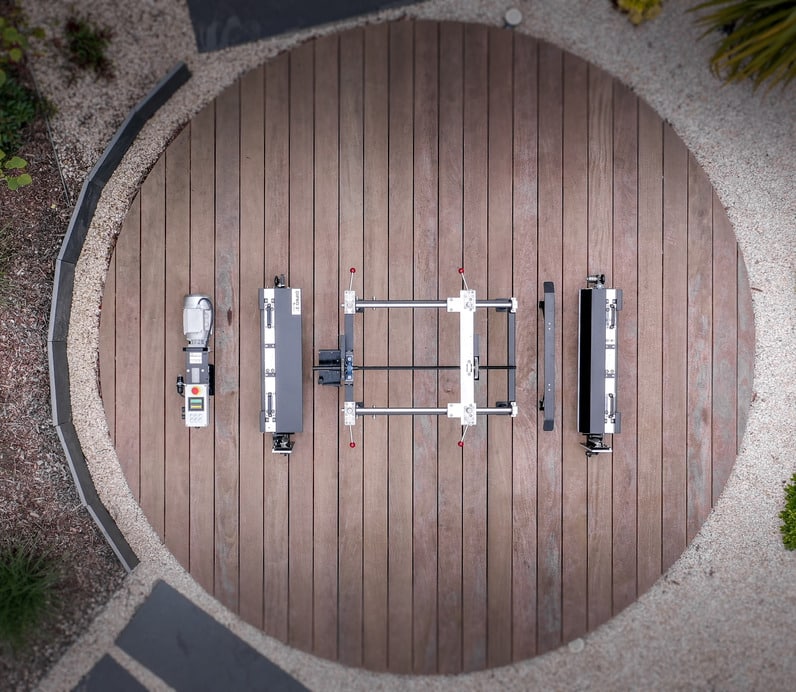

Unlimited maximum width with the removal of one of the profiling trains

Ideal for all curved roofs, such as turrets, apses, diamond-shaped four-sided and more roofs

- Tray bottom width: 2 passes: from 62 to 677 mm

- Sheet width: 2 passes: from 140 to 755 mm

Unlimited maximum width with the removal of one of the profiling trains

Ideal for gaps between openings, such as windows, and at the end of roofing and cladding.

- Tray bottom width: 2 passes: from 60 to 625 mm

- Sheet width: 2 passes: from 150 to 715 mm

Unlimited maximum width with the removal of one of the profiling trains

Ideal for starting points at projecting eaves and jambs, for roofing and cladding.

- Tray bottom width: 2 passes: from 95 to 660 mm

- Sheet width: 2 passes: from 165 to 730 mm

Unlimited maximum width with the removal of one of the profiling trains

Ideal for wall terminations in roofing or cladding.

- Tray bottom width: 1 pass: from 45 to 710 mm

- Sheet width: 1 pass: from 90 to 755mm

Unlimited maximum width with the removal of one of the profiling trains

Ideal for wall starts and transitions in roofing or cladding.

- Tray bottom width: 1 pass: from 55 to 710 mm

- Sheet width: 1 pass: from 90 to 745 mm

Unlimited maximum width with the removal of one of the profiling trains

Enjoy the essential.

We stand by your side.

Developed with roofers

Each machine undergoes rigorous testing and inspection

Easy maintenance

CE certification

Designed and manufactured in France

2-year warranty

Proactive and dedicated support team