Cut-to-length

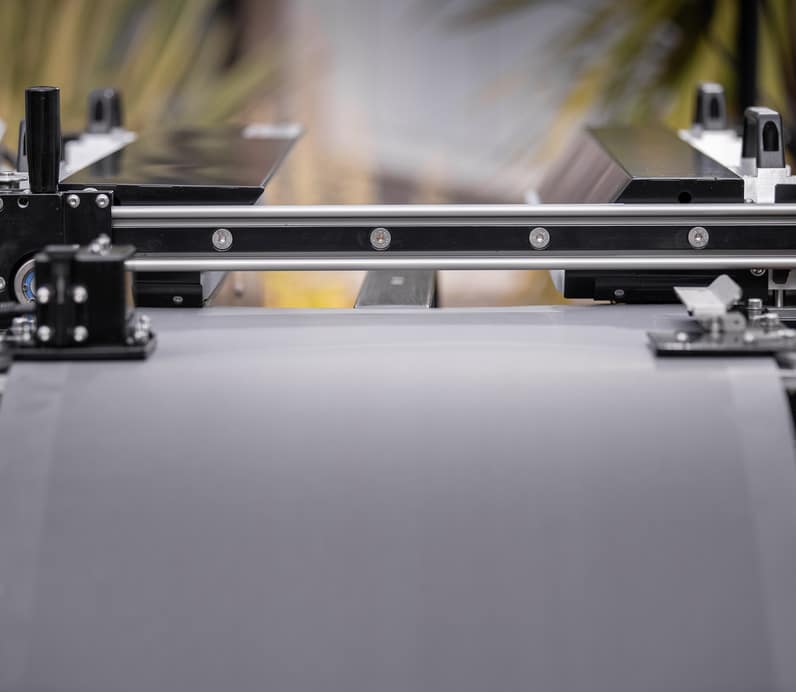

The cut-to-length option represents a significant advancement in the field of production. Thanks to intuitive programming via the control box, it offers unparalleled flexibility. Easily choose the desired number and length of bins to customize the manufacturing process. Its quick and tool-free installation ensures that you are 100% autonomous. With remarkable precision, the cutting is performed with durable blades, ensuring consistent quality. By placing the cutting upstream of profiling, this option optimizes material usage and reduces potential waste. Whether in single or batch production, you contribute to and respect the surrounding beauty.

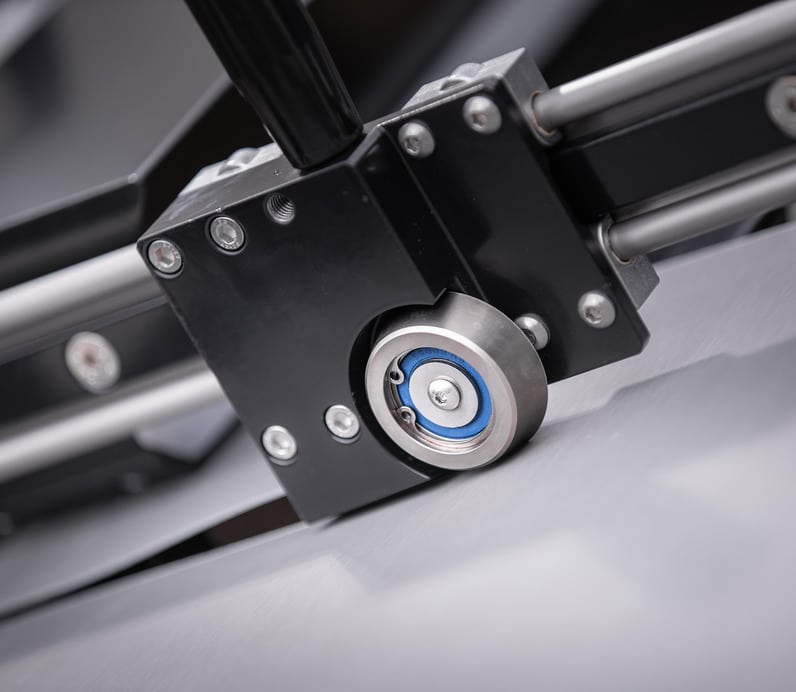

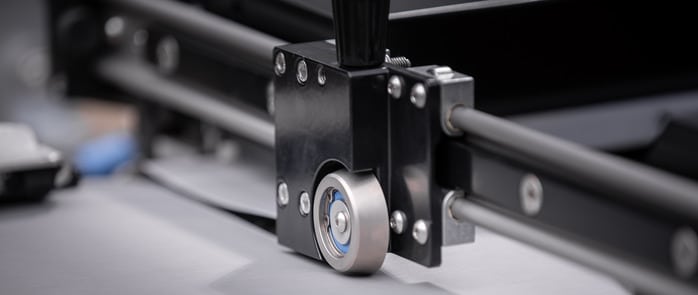

100% precise cutting

thanks to the

Double Circular Blade system

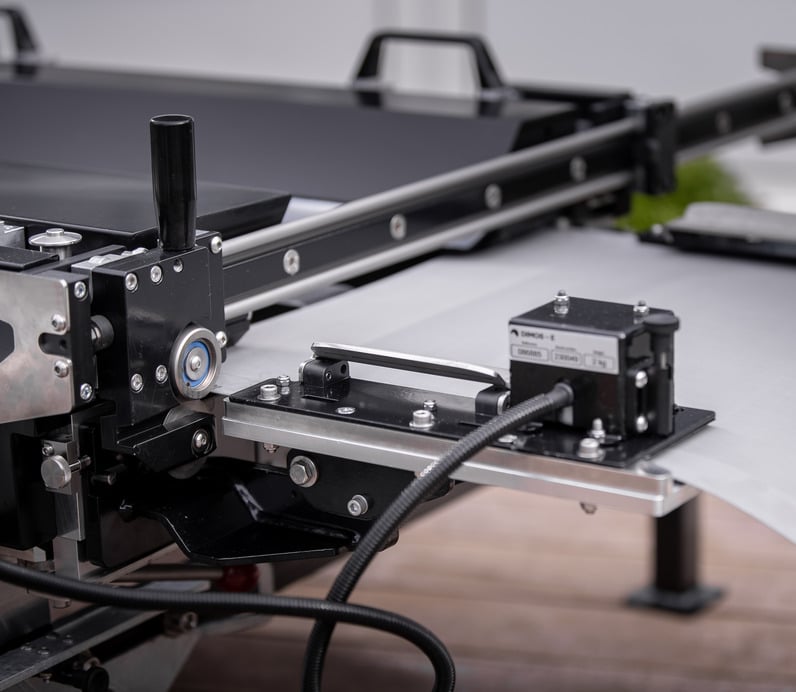

2 seconds

installation with

Plug & Play technology

100% programmable

by selecting

the quantity and length of panels

Enjoy the essential.

No tools assembly.

Assembled and disassembled in no time. Each part can be plugged in by yourself whenever you want, no need to return to the factory! All modules can be carried by one or two people, depending on the weight.

Machines & options available.

Be surer than sure.

The Dipro3x profiling machine offers versatility and precision, capable of profiling a wide range of materials including steel, aluminum, copper, zinc, and stainless steel. It ensures high-quality results across various thicknesses, even accommodating noble materials such as 0.8mm copper. With its advanced technology, the Dipro3x consistently delivers impeccable standing seam roofs, making it an ideal choice for roofing projects that demand excellence.

Yes, the Dipro3x profling machine would be suitable for you. It is exceptionally user-friendly, designed for anyone, regardless of their knowledge about metal profiling. It boasts intuitive and straightforward operation, ensuring simplicity, safety, and ease of use. Suitable for all types of roofers, from novices to experts.

Yes, the profiling machine Dipro3x is incredibly versatile. It's modular, allowing easy transportation in trucks or vans, and capable of profiling even on roofs with pitches <7°. With the Mobility+ option, it can navigate various terrains, including gravel, and cross sidewalks up to 15 cm high. Inside buildings, the machine can be moved vertically with ease. It effortlessly fits through doors and elevators.

Test the Dipro3x machine with your dealer's assistance, either in their showroom or experience center. To purchase, contact your regular dealer or request a quotation directly from the machine's page. You can also include all the options that interest you.

![[object Object]](https://dipro3.dimos.fr/wp-content/uploads/2024/03/Cut-to-length-1-1.jpg)